40+ Years of Industry Experience

Doright has been manufacturing non sparking wrenches for over four decades, serving industries such as oil & gas, chemical plants, mining, and shipbuilding. Tested in demanding work environments, our brass non-sparking wrenches are trusted by professionals for their proven reliability and safety.

Strong Manufacturing Capacity

With a production base covering 186,000㎡ and an annual output of 1,500×10⁴pieces, Doright ensures a stable and large-scale supply of non sparking wrenches. As a distributor, you don’t have to worry about stock shortages. With Doright’s strong capacity, you can handle urgent customer demands, fulfill bulk orders with ease, and expand your business without supply chain concerns.

Fast and Flexible Delivery

By keeping stock across multiple locations, Doright shortens delivery times and minimizes the risk of supply interruptions, helping you maintain a smooth workflow.

Advanced Manufacturing Technology

By adopting world-class forging and heat-treatment techniques, we guarantee consistent hardness, strength, and precision for every non-spark wrench. This ensures reliable performance even under heavy-duty industrial use.

Premium Raw Materials

All non sparking wrenches are made from high-grade copper-based alloys such as aluminum bronze and beryllium bronze. Our wrenches not only deliver excellent spark resistance but also ensure long-lasting durability and corrosion resistance in harsh chemical or marine environments.

Certified Quality Assurance

Every non sparking wrench is tested in our CNAS-accredited laboratory to ensure consistent hardness, durability, and spark resistance before shipment. This minimizes after-sales issues for dealers and ensures that end-users receive tools they can rely on.

Safety and Compliance

Beyond internal testing, Doright tools also meet international safety standards, including OSHA, JISM, and DIN. This dual assurance means the our non spark wrenches are not only factory-verified but also recognized by regulatory bodies, ensuring smooth acceptance in highly regulated industries.

Versatility in Application

From non-sparking adjustable wrenches to combination spanners, our tools are designed for a wide range of tasks in hazardous environments, giving professionals the flexibility they need to work safely and efficiently.

Non-Sparking Adjustable Wrench: A versatile design that fits various nut and bolt sizes, ideal for general maintenance.

Motor Wrench: Specially made for mechanical assembly and equipment maintenance where precision and safety are critical.

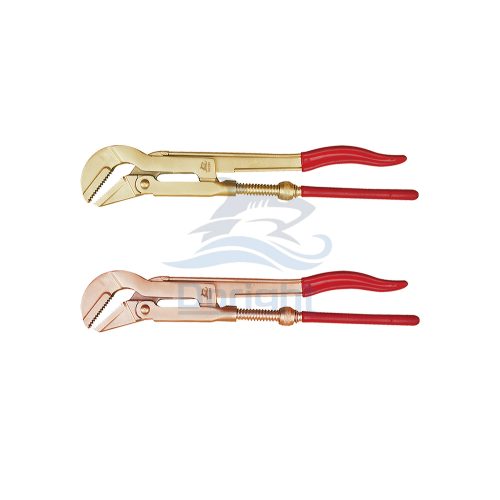

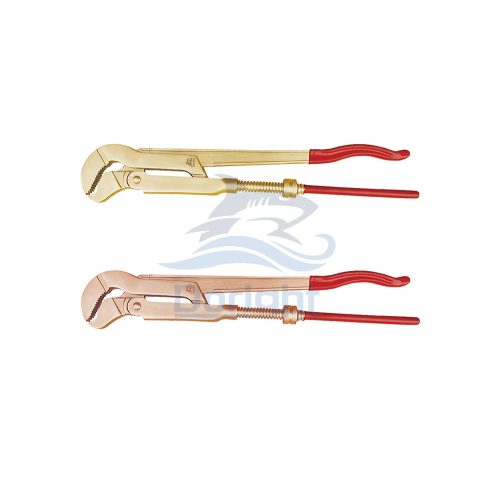

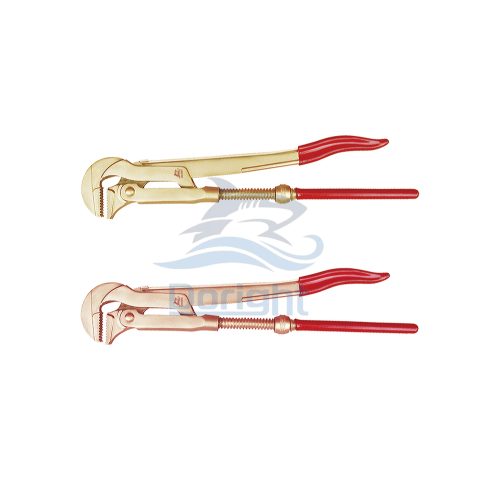

Swedish Type Wrench: Known for its ergonomic design and firm grip, suitable for heavy-duty tightening tasks.

Chain Pipe Wrench: Provides strong holding power for round surfaces such as pipes and cylindrical parts.

Combination Wrench: Offers both open-end and ring-end functions in one tool, making it practical for everyday use in industrial settings.

This is only part of our full range. Contact us today to explore more options tailored to your industry.